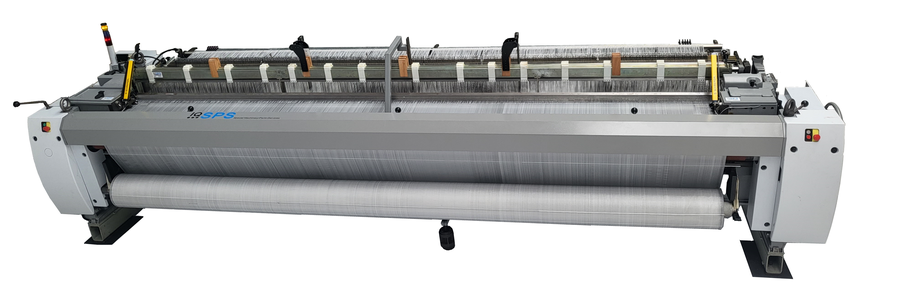

Do you want to answer your customer's wishes for special or extra wide fabrics? In this case the acquisition of a brand new, expensive special weaving machine might not be necessary.

Using our know-how and our experience we upgrade available machines. A modified machine is state-of-art with the use of proven technology at affordable costs.

Our services range from techical specification to commissioning. In this way, the customers receive a state-of-the-art weaving machine with which high-quality products can be produced. The possible areas of application are, above all, in the field of technical fabrics, for example geotextiles, carpet backing primary and secondary, safety textiles and reinforcing textiles for the construction industry, coating carriers, printing grounds, tarpaulins, awnings, fabrics for advertising and many more, just to mention a few possibilities.

Phoenix

SPS 300

SPS150

Possible applications

- Geotech

- Agrotech

- Oekotech

- Indutech

Your Advantages:

- good-value alternative to the purchase of a new machine at a low technical and economical risk

- adapt to new needs

- maintain the solid machine structure

- familiar machine operation

- increased performance

- extend the service life

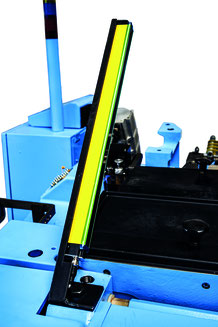

Safety Light Barrier

- active personal protection

- reacts before the moving element can be touched

- simple handling

- rugged construction

- constructed according to the current CE-machine building regulations

- upgradable for the machine types P7100 to P7250 (additional types on request)

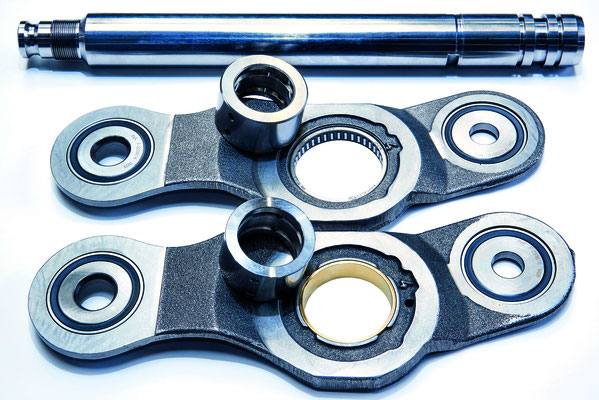

PosiLeno (Groz-Beckert)

- upgrade kit to weave with PosiLeno System from Groz-Beckert to weave up and down leno

- available for all sizes and types of projectile machines

- easy handling

- installation on-site in your factory

- machine can work with maximum speed (rpm) also for Leno fabrics

- lower spare parts consumption

- higher fabric quality

- exclusively available at IQ-SPS

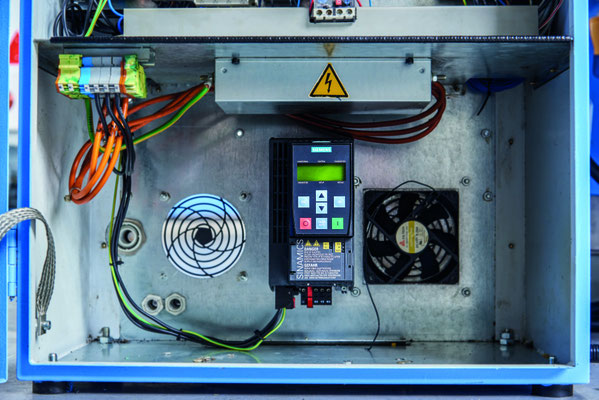

Control Cabinet

- more spacious, more user-friendly

- all controller modules in one place

- installed at weft insertion side

- shorter peripheral cables and thus reduction of possible interfering signals

- shorter walking distances for operation of control cabinet

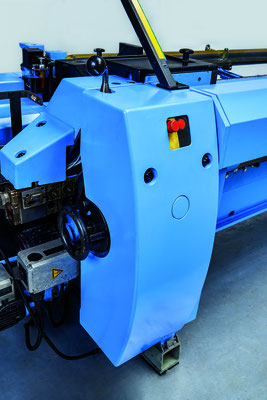

Take-up

- especially designed for heavy and heaviest fabrics

- can be retrofitted to virtually every weaving machine.

- enormous robustness, compact design

- driven first roller.

- extra short fabric support table: reduction of shifting of the weft yarn

- support rollers prevent the bending of the driven rollers

- significant reduction of the so-called recoil of the fell at the beat-up

- special additional frames: existing frames are not subjected to additional loads.

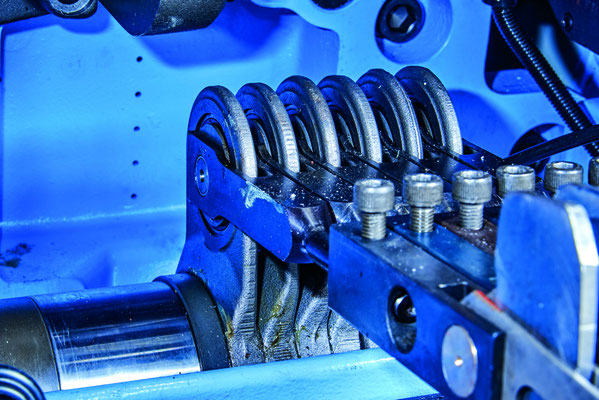

Electronic Let Off Device

- motor with 200N maximum torque

- high torque gear

- 50.000 N axial force

- completely new design

- easy adjustment

With this warp reduction system you can achieve warp pull forces which by far exceed the standard.

Warp Tension Gauge

- optimal warp tension control

- reproducible adjustment of warp tension

- from 2.000 N up to 5.000 N

- easy handling

Lubrication